2.1 Safety Precautions

2.1 Safety Precautions

This section describes precautions regarding installation of the SPARC M10 systems. Be sure to follow the precautions below when performing installation work. Failure to do so may lead to damage to the device or a malfunction.

- Follow all the stated precautions, warnings, and instructions for the chassis.

- Do not insert any foreign object into the chassis openings. Any object that touches a high-voltage part or causes a component to short circuit may lead to fire or electric shock.

- Contact a service engineer for details of chassis inspection.

Safety precautions when working with electricity

- Confirm that the voltage and frequency of your input power match the electric rating described on the system name plate label affixed on the server main unit.

- Make sure to wear a wrist strap when handling the internal disk (HDD/SSD), memory, CPU memory unit (upper/lower unit), or other printed circuit boards.

- Make sure to use grounded power outlets.

- Do not make mechanical or electrical modifications to the chassis. We do not take responsibility for regulatory compliance of a modified chassis.

- Do not disconnect a power cord from the chassis while the power is on.

Safety precautions regarding racks

- Racks must be fixed to the floor, ceiling, or nearest frame.

- The quakeresistant options kit may be supplied with the racks. The use of the quakeresistant options kit prevents the rack from toppling over when the chassis is pulled out from the slide rails for installation or maintenance.

- In the following cases, a safety evaluation must be performed by a service engineer before installation or maintenance.- If the quakeresistant options kit is not supplied and the rack is not fixed with bolts to the floor, a service engineer confirms the safety of the rack, such as by verifying that it does not topple over when the chassis is pulled out from the slide rails.- If the rack is mounted on a raised floor, a service engineer confirms that the floor can withstand the load when the chassis is pulled out from the slide rails. Fix the rack to the concrete floor beneath the raised floor by using the original mounting kit that serves this purpose.

- If multiple chassis are mounted in the rack, perform maintenance on one chassis at a time.

Safety precautions regarding installation work

- With this chassis installed in a closed or multi-unit rack assembly, the ambient temperature inside the rack operating environment may be greater than the ambient room temperature. Therefore, consideration must be given to installing the chassis in an environment compatible with the manufacturer's maximum rated ambient temperature.- Consideration of air-conditioning adjustments, such as with air circulation, is needed to prevent the ambient temperature inside the rack from exceeding the maximum ambient operating temperature of this chassis.- Maximum ambient operating temperature of this chassis: 35°C

- The installation of the chassis in a rack should allow for sufficient air flow for the chassis to operate safely.- This chassis has ventilation slits at the front and rear of the chassis.- To prevent overheating, do not cover or close these ventilation slits.

- The mounting of the chassis in the rack should not create any hazardous condition due to uneven mechanical loading. To keep the entire rack stable, fix the rack to the wall or floor by suitable means.- Be careful not to injure yourself or others when installing the chassis in the rack.- Do not install this chassis in the rack if the chassis may make the entire rack unstable.- Weight of this chassis in the maximum configuration:

Model SP-4SBB (SPARC M10-4S): 60 kg

Model SP-PCI-BOX (SPARC PCI-BOX): 22 kg - If the chassis is supplied power from a power strip or the service outlet of another chassis, it may overload the power strip or the power cord of the other chassis.- Confirm that the power strip or the power cord of the service outlet exceeds the combined ratings of all the equipment to which it supplies power.

Electrical ratings of this chassis:

Model SP-4SBB: 200-240 VAC, 16.0-13.4 A, 50/60 Hz, Single phase (Maximum 2 inputs)

(For India and Taiwan only: 200-240 VAC, 14.7-13.4 A, 50/60 Hz, single phase (Maximum 2 inputs))

Model SP-PCI-BOX: 100-120/200-240 VAC, 5.0-4.2/2.5-2.1 A, 50/60 Hz, Single phase (Maximum 2 inputs) - Be sure to securely ground the rack-mounted equipment. Pay particular attention to power supply connections other than the direct connections to branch circuits (e.g., use of power strips).

|

- Install this equipment such that it is near a wall and a power outlet is easily accessible.- Rack configuration

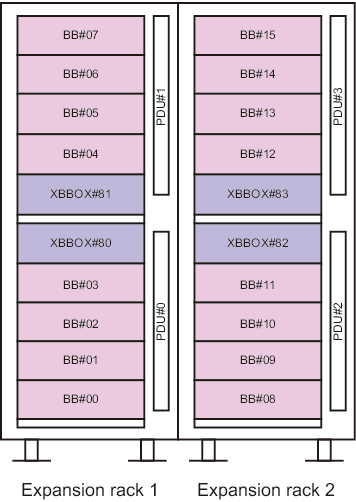

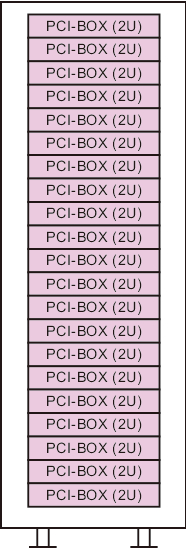

| Note - If the combination of chassis mounted in an installed rack differs from the specifications described in Figure 2-1 or Figure 2-2, re-verification by an appropriate safety certification body is necessary. For installation of the product, begin at the bottom of the rack. |

|

Figure 2-1 Rack configuration (for the 16BB configuration)

|

|

|

Figure 2-2 Rack configuration (for the PCI expansion unit)

|

|

< Previous Page | Next Page >