2.4.6 Points of Concern During Installation of an Expansion Rack

2.4.6 Points of Concern During Installation of an Expansion Rack

The points of concern when installing the expansion rack or main product are as shown below.

- When the expansion rack is installed, confirm that the access route has the dimensions larger than the packaged unit dimensions listed below.- Simplified packaging (*1)

: Width 700 mm x Depth 1050 mm x Height 2000 mm (Width 27.6 in. x Depth 41.3 in. x Height 78.7 in.)- General packaging

: Width 1260 mm x Depth 1264 mm x Height 2160 mm (Width 49.6 in. x Depth 49.8 in. x Height 85.0 in.)

| *1 Simplified packaging means covered only by a plastic sheet, etc. and not packed in a crate or cardboard. |

- The expansion rack is shipped with a SPARC M12-2S and crossbar box mounted in the rack. When it is difficult to install the packaged product, open the package as necessary and install it.

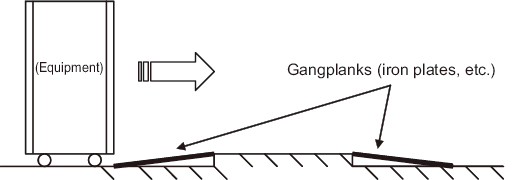

- When there are steps in the access route, gangplanks may be required.

|

Figure 2-10 Example of Using Gangplanks

|

|

- Since the maximum weight of the expansion rack is about 960 kg with packaging and 780 kg without packaging, confirm beforehand that there is no problem with the access route.

Example: Floor condition of access route

Confirm that the floor has sufficient load bearing, and that the casters do not sink into the floor nor get caught on the floor. - When installing this device on an upper or lower floor, confirm beforehand that an elevator is available and has sufficient load bearing for the weight of the device.

- When installing this device, push on the lower half of the rack to prevent toppling. Depending on the devices mounted in this rack, the center of gravity may be high.

Also, do not to push from the side. That may cause the rack to topple over. - Since pushing the air inlet portion near the center of the front door may cause deformation of the door, push at the corner of the door.

- Carrying the main product mounted in the rack from a cold location to a warm room will cause condensation inside the product.

Control the room temperature so that the temperature rise per hour does not exceed 15°C (59°F) to prevent condensation. Concerning the development of condensation, see the following table.

| Room Temperature °C (°F) | Remarks | ||||||||

| 10 (50) |

15 (59) |

20 (68) |

25 (77) |

30 (86) |

35 (95) |

40 (104) |

|||

| Relative humidity (%) |

20 | -7 |

-5 |

-3 |

1 | 5 | 9 | 13 | Example: When the room temperature is 25°C (77°F) and the temperature of the unit is 17°C (63°F) or lower, condensation will develop. |

| 40 | -3 |

2 | 7 | 11 | 16 | 20 | 24 | ||

| 60 | 3 | 8 | 13 | 17 | 22 | 26 | 31 | ||

| 80 | 7 | 12 | 17 | 22 | 26 | 31 | - | ||

| 90 | 9 | 13 | 19 | 24 | 29 | 34 | - | ||

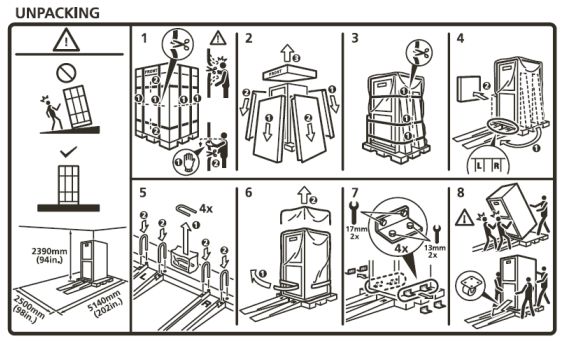

- When using general packaging, pay attention when opening the packaging. Follow the next procedure to open the rack packaging. This work is unnecessary for simplified packaging.a. Place the packaged rack at flat location. The necessary service area is displayed on the packaging box. Refer to the diagram and select a service area.b. Cut the PP bands fastening the packaging materials with scissors etc. When cutting PP bands, beware that the band can snap back and cause injury. Make sure to work at a height lower than your head, and hold down a PP band with one hand when cutting.c. Remove the packaging materials.d. Fasten the ramp at the specified location. The fastening location is displayed on the packaging box.

Secure the ramps firmly with the four supplied U-shaped brackets. When the fastening is not sufficient, the rack may become unstable when the rack is removed from the palette, which is dangerous.e. Remove the plastic bag around the rack.f. Remove four brackets fastening the rack and palette using a spanner or box wrench (size 13 or 17).g. Dismount the rack from the palette. Perform this work with three or more persons. Do not stand in front of the moving direction of the rack. It is dangerous when the rack is unstable.

|

Figure 2-11 Opening Procedure for General Packaging

|

|

< Previous Page | Next Page >