2.4.1 Mounting Conditions for General Racks

2.4.1 Mounting Conditions for General Racks

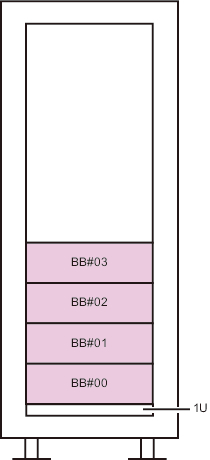

1BB configuration/4BB configuration with direct connections between chassis

The SPARC M12-2S and the PCI expansion unit are designed to be mounted in a 19 inch rack.

If the SPARC M12-2S units are connected by crossbar cables, mount the units side by side in a rack with no gap between them.

If the SPARC M12-2S units are connected by crossbar cables, mount the units side by side in a rack with no gap between them.

|

Figure 2-2 Chassis Mounting Locations (Corresponding to BB-IDs) for the 4BB Configuration

|

|

| Note - Since, during SPARC M12-2S maintenance, the cable support at the rear of the chassis moves underneath the chassis, do not mount anything on the lowest shelf (1U) of the rack. |

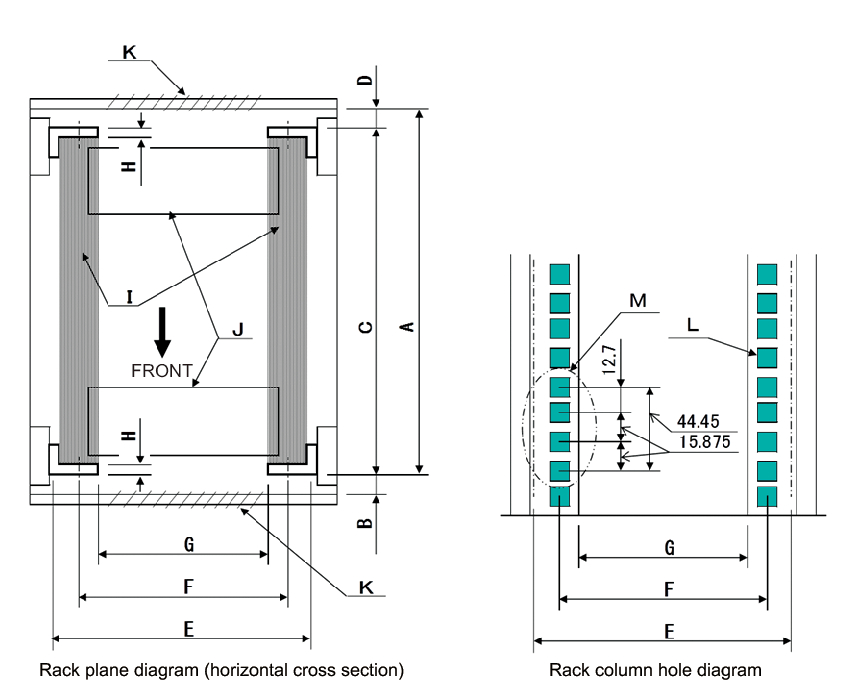

For mounting in a third-party rack, it is the customer's responsibility to confirm that the rack specifications match the specifications and requirements for the SPARC M12-2S (see Figure 2-3 and Table 2-3).

|

Figure 2-3 Dimensional Drawings for Third-Party Rack Checks

|

|

| Note - The dimensions shown in the conditions do not include any protrusions. |

| Description | Condition | Letter in Figure |

|---|---|---|

| Rack type/Compliance standards | Equipment rack/EIA standard-compliant | -- |

| Dimension between rear door (inside) and front column | SPARC M12-2S: At least 908 mm (35.7 in.) PCI expansion unit: At least 848 mm (33.4 in.) |

A |

| Dimension between front door (inside) and front column | SPARC M12-2S: At least 32 mm (1.3 in.) PCI expansion unit: At least 24 mm (0.9 in.) |

B |

| Dimension between front and rear columns | Within adjustment range of rack mount kit Adjustment range of mount kit for each server SPARC M12-2S: 630 mm (24.8 in.) to 840 mm (33.1 in.) PCI expansion unit: 630 mm (24.8 in.) to 840 mm (33.1 in.) |

C |

| Dimension between rear door (inside) and rear column | SPARC M12-2S: At least 158 mm (6.2 in.) PCI expansion unit: At least 158 mm (6.2 in.) |

D |

| Front panel mounting space of chassis | At least 483 mm (19.0 in.) | E |

| Distance between left and right chassis attachment holes (common to front and rear columns) | 465 mm (18.3 in.) |

F |

| Distance between left and right columns (common to front and rear columns) | At least 450 mm (17.7 in.) | G |

| Column thickness | 2 mm (0.08 in.) to 2.5 mm (0.1 in.) |

H |

| Structures other than columns | Rack has no structures between front and rear columns | I |

| Cable hatch | Rack has hatch on bottom surface, rear door, or elsewhere | J |

| Area of door vent openings | Front door: At least 73% of door area Rear door: At least 73% of door area |

K |

| Size of attachment holes (common to front and rear columns) | Square hole with sides longer than 9.2 mm (0.36 in.) and up to 9.8 mm (0.38 in.) (*1), or M6 screw hole | L |

| Vertical pitch of chassis attachment holes (common to front and rear columns) |

EIA standards, universal pitch | M |

| Door opening angle | Door opens to 130° | -- |

| Strength | Rack has necessary strength/load capacity for mounting chassis | -- |

| Grounding | Rack and units can be grounded | -- |

| Toppling prevention measures | Rack can be prevented from toppling over | -- |

| Earthquake resistance measures | Earthquake resistance measures can be implemented for rack | -- |

| *1 If the SPARC M12-2S or PCI expansion unit has square holes with sides of length 9.0 mm (0.35 in.) to 9.2 mm (0.36 in.), a separate rack mount kit must be ordered. | ||

- Mounting on the lowest shelf of the rack

For the SPARC M12-2S, the cable support at the rear of the chassis can move underneath the chassis during maintenance, so do not mount anything on the lowest shelf (1U) of the rack. (See Figure 2-2) - Relocation

Depending on the customer's situation, if the SPARC M12-2S is mounted and used in a general rack, remove every SPARC M12-2S from the rack at the following time. Remove all of them when relocating the rack within the room or building or to another building, or when changing the system configuration and changing the installation location due to expansion or reduction.

After moving and securing the general rack to the new location, mount each SPARC M12-2S. - Other conditions

In addition to structural conditions, the following condition must be taken into consideration.- Install the rack while taking into consideration the cooling inside the chassis so that the temperature of the products mounted in the rack meets the temperature conditions. For details, see "2.5 Checking Environmental Conditions." Particularly, make sure that exhaust from the chassis does not re-enter the chassis through the air intakes. This requires measures such as covering the front and rear of empty spaces inside the rack.

< Previous Page | Next Page >